Military Machining of Optical Components

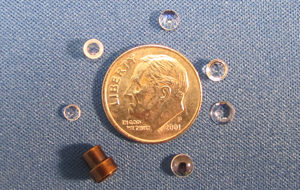

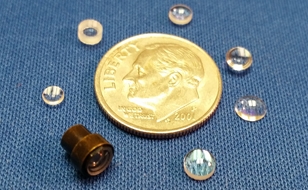

When customers need an innovative optical solution, they contact our dynamic team at Optics Technology, Inc. We have a wealth of experience in the field of optical component design and fabrication as well as micro-machining and optomechanical assembly. The assembly highlighted here is a high-resolution miniature camera lens that was produced as part of a US government contract. The assembly includes eight elements, with one of the elements having a center thickness of only 250 microns. The overall assembly is .1875″ in diameter, less than .25″ in length, and is comprised of optical glass and brass materials.

When customers need an innovative optical solution, they contact our dynamic team at Optics Technology, Inc. We have a wealth of experience in the field of optical component design and fabrication as well as micro-machining and optomechanical assembly. The assembly highlighted here is a high-resolution miniature camera lens that was produced as part of a US government contract. The assembly includes eight elements, with one of the elements having a center thickness of only 250 microns. The overall assembly is .1875″ in diameter, less than .25″ in length, and is comprised of optical glass and brass materials.

We have been working with government agencies for 30 years and understand the unique requirements of government projects. For this particular contract, secret clearance was required for all employees, including all of the lens designers, engineers, and precision fabricators who were directly involved in the project. Resolution target testing was used to verify the accuracy of the lens for this surveillance application.

Every component included in this assembly was designed, fabricated, and assembled in-house with a total lead time of only twelve weeks from design to delivery. The ability to provide turnkey services for customers not only reduces the overall lead time and general supply chain issues that result from sourcing with multiple vendors, it is very advantageous for projects such as this one, where confidentiality is key. As a result of our work on this project, we received a citation of merit from the US government. For additional information about this precision optical fabrication and assembly project, contact us directly.

Military Machining of Optical Components Highlights

- Project Name & Description

8 Element miniature camera lens, f/1.3

High resolution camera lens for the US Government.

- Capabilities

Miniature optics mechanical fabrication and design.

- Equipment Used to Manufacture Part

CNC Mill

CNC Lathes

Various Optical Polishers

- Overall Part Dimensions

Less than .25in long

3/16in diameter

- Tightest Tolerances

± .0001 in

- Material Used

Optical Glass

Brass

- Industry Use

Surveillance

- In Process Testing/Inspection Performed

Resolution Target

- Delivery/Turnaround Time

12 Weeks from Design to Delivery