National Labs & Universities Invo Reflectance Confocal Microscopy Lens Systems

In addition to manufacturing commercial optical products, at Optics Technology, Inc., we partner with universities and other research institutions to develop, engineer, and fabricate prototype products. The project highlighted here was performed in partnership with American University. We worked with researchers at the university to design and fabricate a new lens that is designed for use in the medical industry. The lens is used to detect precancerous in vivo in the human oral cavity. Advances in optical technology continue to allow the medical community to diagnose dangerous diseases more accurately and earlier on, which can significantly increase the likelihood of remission and recovery.

In addition to manufacturing commercial optical products, at Optics Technology, Inc., we partner with universities and other research institutions to develop, engineer, and fabricate prototype products. The project highlighted here was performed in partnership with American University. We worked with researchers at the university to design and fabricate a new lens that is designed for use in the medical industry. The lens is used to detect precancerous in vivo in the human oral cavity. Advances in optical technology continue to allow the medical community to diagnose dangerous diseases more accurately and earlier on, which can significantly increase the likelihood of remission and recovery.

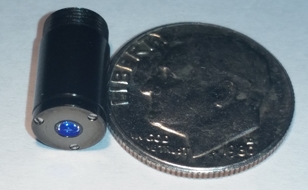

The customer chose us as a partner on this project as a result of our extensive optical design and fabrication experience. Our experience in precision micro-machining allows us to fabricate new designs with unrivaled accuracy. The optical glass lens is encased in stainless steel and measures .75″ in length by .375″ in diameter. To maintain the level of precision required, tolerances were held to as tight as ±0.0002″. To meet the required performance specifications, the lens assembly had to be completely air tight. Wave front testing was required to verify the accuracy of the assembly.

The customer was so pleased with the quality and workmanship that went into this project that they included fabrication details in their research paper written on this project. This small scale precision optical manufacturing project was completed with a total lead time of only 12 weeks. For additional details regarding this optical research and development project, contact us directly.

Lens System Highlights

- Project Name & Description

Lens design & Manufacturing that was geared towards imaging of the human oral cavity for detection of precancerous in vivo. This was an American University.

- Capabilities

Micro Optical fabrication and assembly and design.

- Equipment Used to Manufacture Part

Convention Optical Equipment

- Overall Part Dimensions

3/4in long

3/8in diameter

- Tightest Tolerances

± .0002 inches

- Material Used

Optical Glass

Stainless Steel

- Industry Use

Study

- In Process Testing/Inspection Performed

Wave Front Testing

- Volume

Small

- Delivery/Turnaround Time

12 Weeks

- Delivery Location

USA